Batteries play a crucial role in powering homes, businesses, and even entire grids, storing energy for when it is needed most. Despite their importance, these systems can face a serious hazard: thermal runaway.

What is thermal runaway in batteries? It occurs when a battery generates heat faster than it can dissipate it. This creates a chain reaction of rising temperatures and chemical reactions.

Let’s see why battery thermal runaway happens and how careful design, monitoring, and maintenance can safeguard your energy systems.

Causes of Battery Thermal Runaway

Several factors can trigger thermal runaway in batteries, ranging from manufacturing issues to user-related errors:

· Internal Short Circuits

Manufacturing defects can create weak points within battery cells. During production, metal particles may become trapped inside, piercing the separator between electrodes. Another common cause is dendrite formation—metal growths that develop during charging. Once an internal short occurs, current flows directly between electrodes, generating excessive heat and initiating thermal runaway.

External Factors

Overcharging forces too much energy into a battery cell, producing heat and increasing internal pressure. High ambient temperatures can further exacerbate the situation. Physical damage, such as drops, may puncture cells, allowing dangerous chemical reactions to begin.

Chemical Instability

Battery electrolytes can become unstable under extreme conditions. Elevated temperatures break down the electrolyte, releasing flammable gases and generating heat. These chemical reactions accelerate the thermal runaway process, with each reaction making the next one more likely.

Consequences of Thermal Runaway

Battery thermal runaway creates both immediate and long-term dangers. The effects extend beyond the battery itself. They impact users, devices, and the environment:

Immediate Risks

Fire is the most visible danger. As batteries overheat, they can ignite nearby materials, and in severe cases, internal pressure builds until the casing ruptures, causing an explosion. These incidents release toxic fumes such as hydrogen fluoride, which are far more dangerous than smoke alone, posing serious health risks to anyone nearby.

Long-Term Risks

The damage often extends beyond the battery. Excessive heat can destroy electronic circuits and melt plastic housings, leaving devices unusable. Even after the initial event, safety hazards remain, and environmental impacts can be severe. Leaking batteries release toxic substances that contaminate soil and water, causing long-lasting environmental harm.

Economic Costs

Thermal runaway also carries significant financial consequences. Replacing damaged devices often costs more than the batteries themselves, while equipment downtime disrupts business operations. Insurance claims for battery fires can reach millions annually, and the cumulative economic impact of these incidents totals billions.

How Can Battery Thermal Runaway Be Prevented?

Preventing battery thermal runaway depends on multiple layers of protection, with Battery Management Systems (BMS) serving as the primary defense. These electronic systems continuously monitor battery conditions and respond immediately when dangerous situations arise.

1. Real-Time Monitoring Systems

Voltage sensors detect potential cell problems at an early stage, while current sensors identify abnormal power flows and temperature sensors track heat buildup. Advanced BMS units constantly check these parameters, and any irregularities trigger protective measures to keep the battery safe.

2. Cell Balancing Technology

Because individual battery cells charge at different rates, weaker cells can become overstressed. Cell balancing technology redistributes energy among cells, preventing overcharge and over-discharge. Active systems perform this balancing continuously during operation, maintaining overall battery stability and extending lifespan.

3. Automatic Safety Cutoffs

BMS units are equipped with automatic safety cutoffs that disconnect batteries when hazardous conditions are detected. Overcurrent protection halts excessive power flow, and thermal cutoffs activate if temperatures rise too high. By combining multiple cutoffs, these systems ensure rapid, reliable protection against thermal runaway.

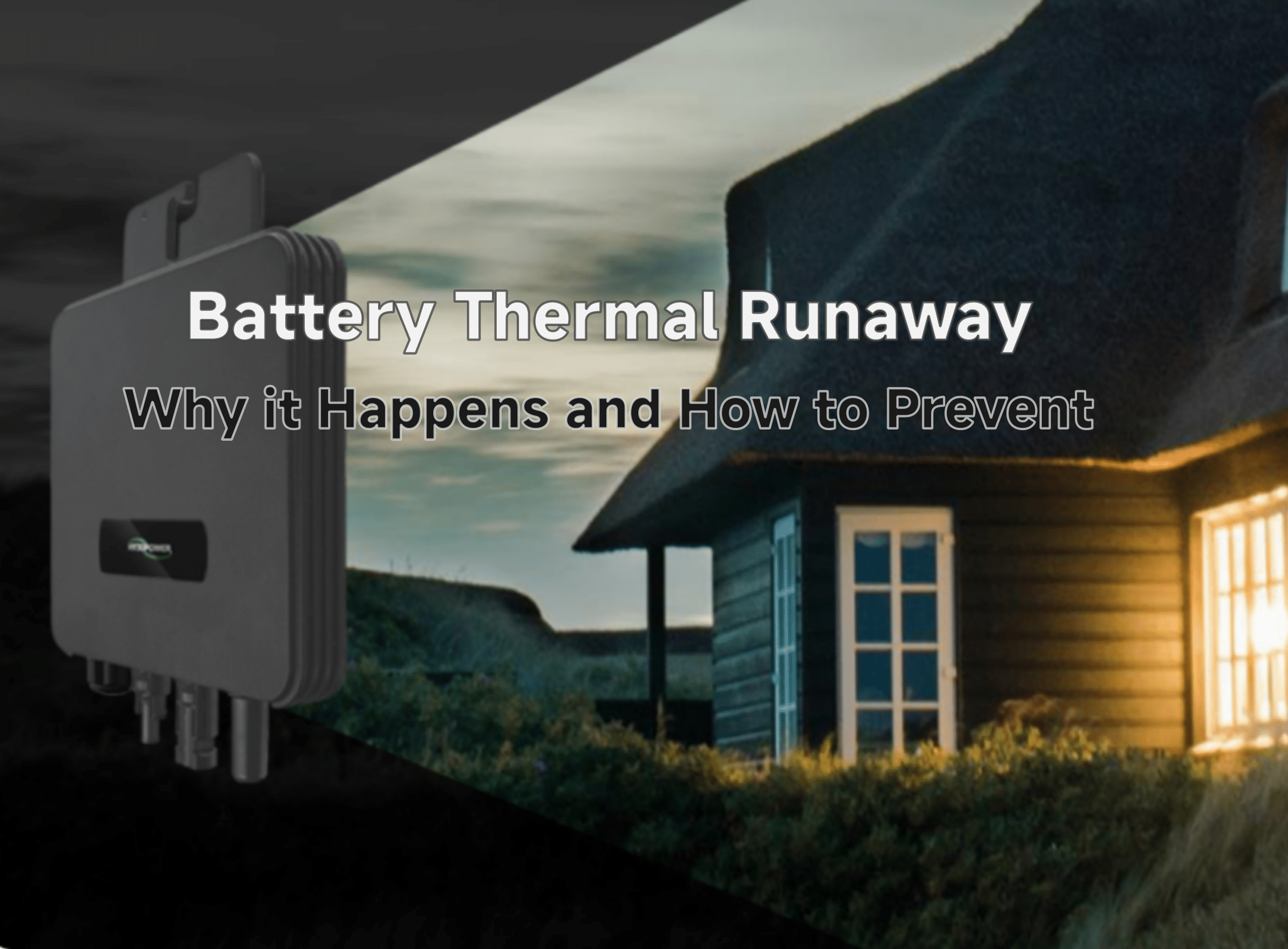

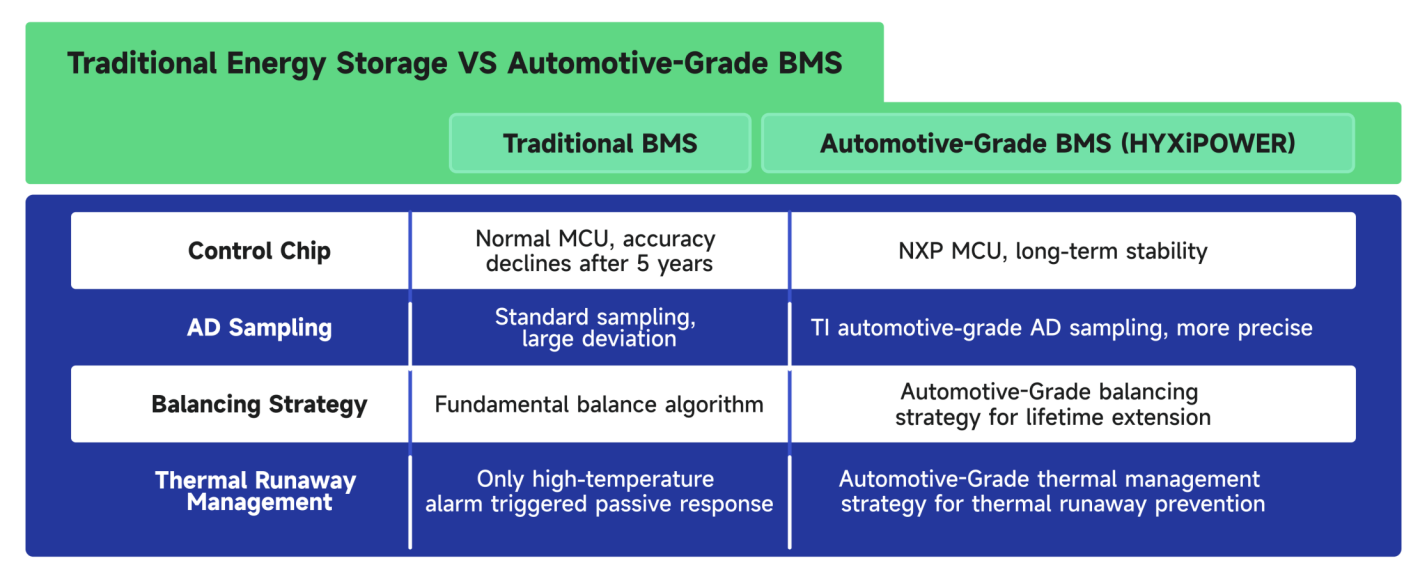

At HYXiPOWER, we’ve taken battery safety to the automotive grade level. Our advanced BMS technology incorporates all these protective features and more. We use premium components like NXP MCU processors and TI sampling chips for maximum precision. Our three-layer safety approach involves automotive-grade materials throughout:

Core Layer: Integrated molding process reduces fracture risk by 99%.

Brain Layer: Self-developed BMS with thermal protection and cell balancing.

Armor Layer: 3mm stainless steel casing with IP67-rated connectors.

Real-time Monitoring: Done with high-precision measurements and rapid response.

Suspended Cell Architecture: Prevents electrical shock risks by 99%.

Conclusion

Battery thermal runaway is a serious safety concern, triggered by internal defects and external factors that can lead to fire, explosion, and environmental damage. Advanced prevention technologies reduce these risks, with proper monitoring and safety cutoffs providing reliable protection.

At HYXiPOWER, our automotive-grade standards deliver the safest and most reliable energy storage solutions. Don’t wait for a safety risk! Visit our website now to explore our full product range and contact our experts to secure the perfect energy storage solution for your needs!